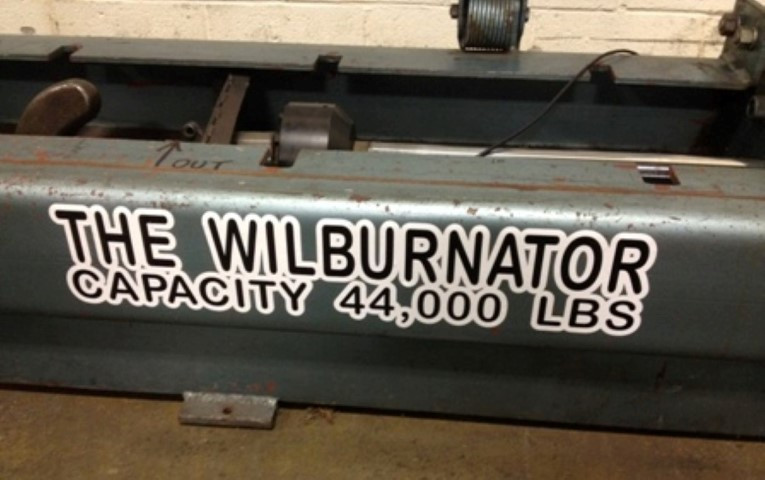

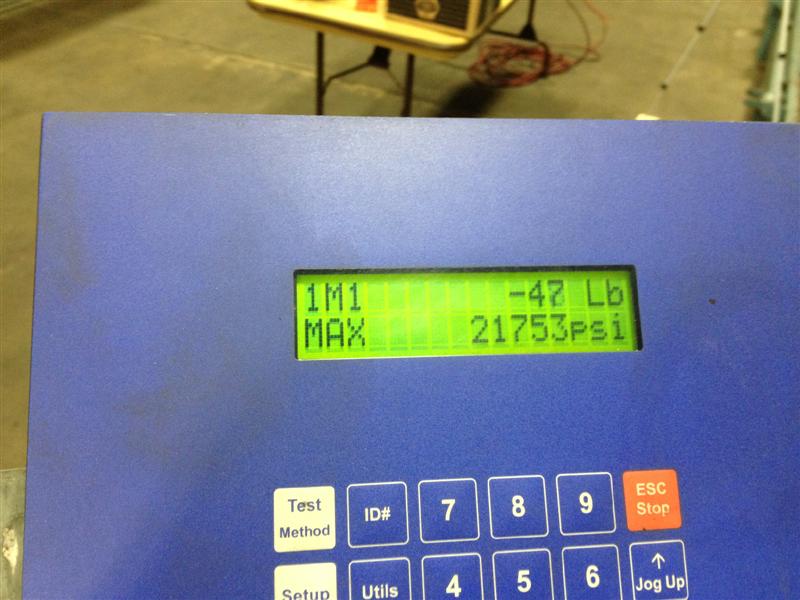

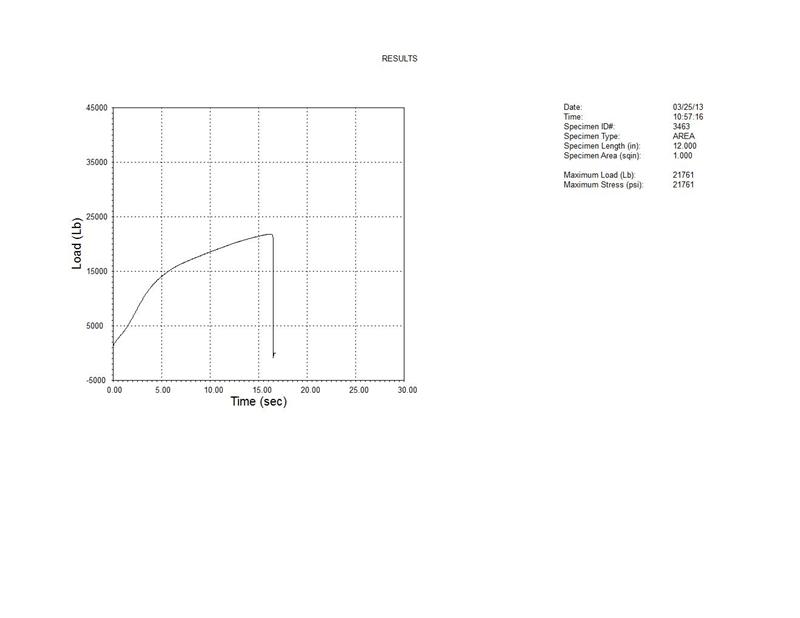

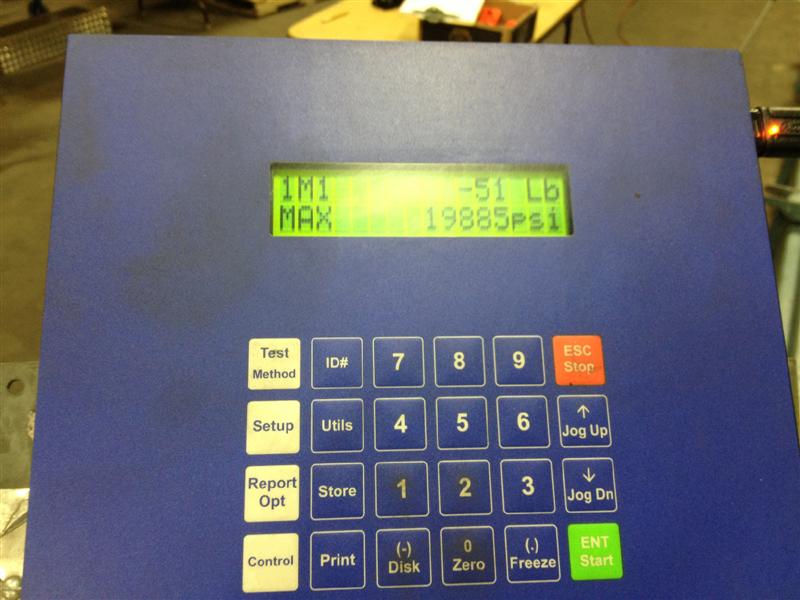

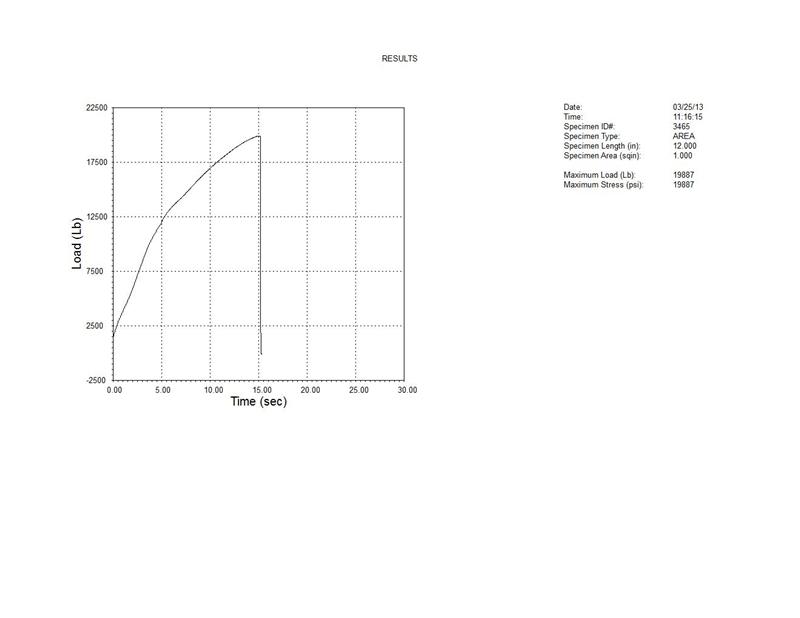

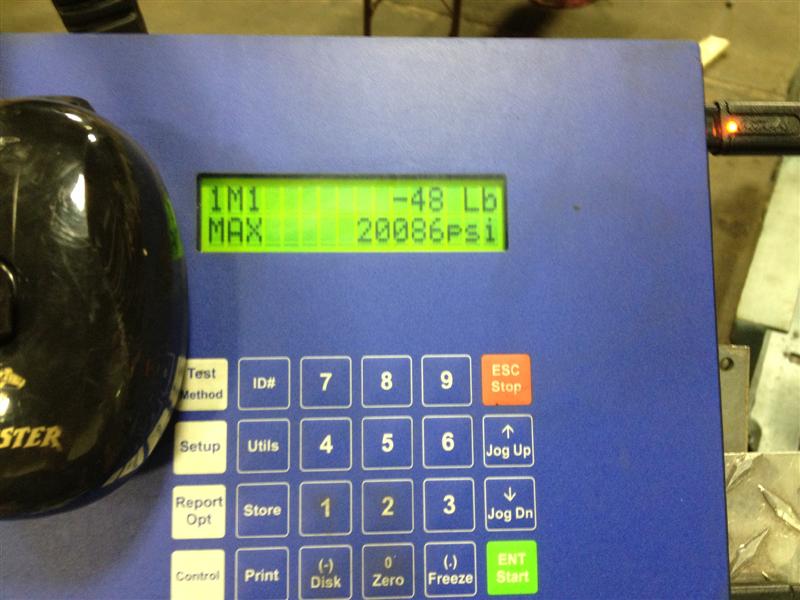

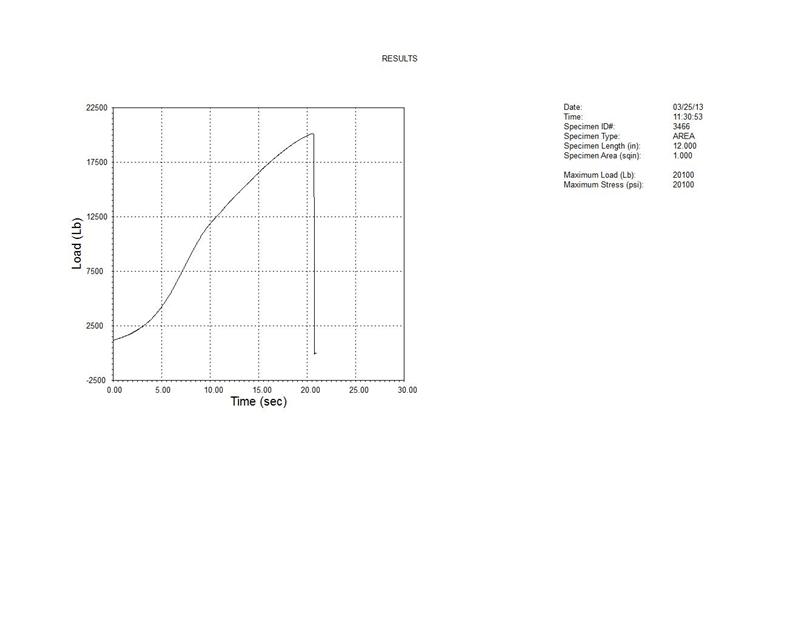

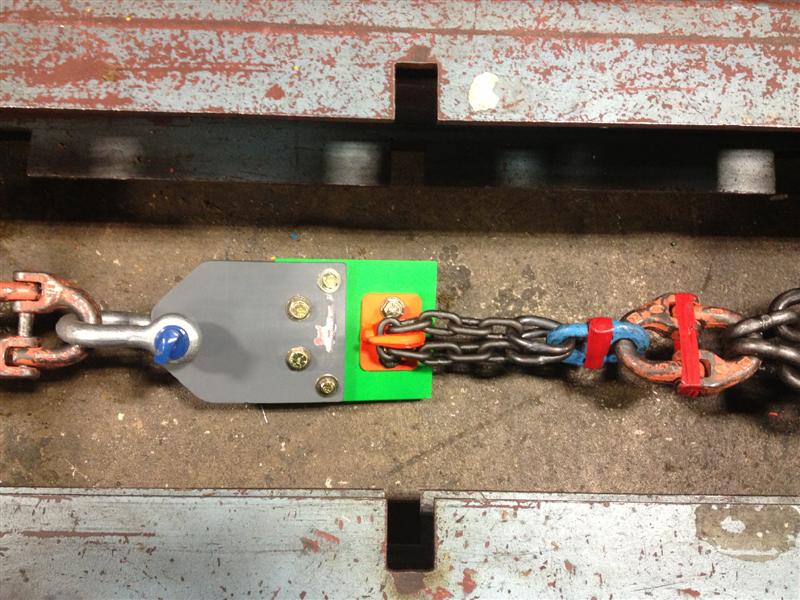

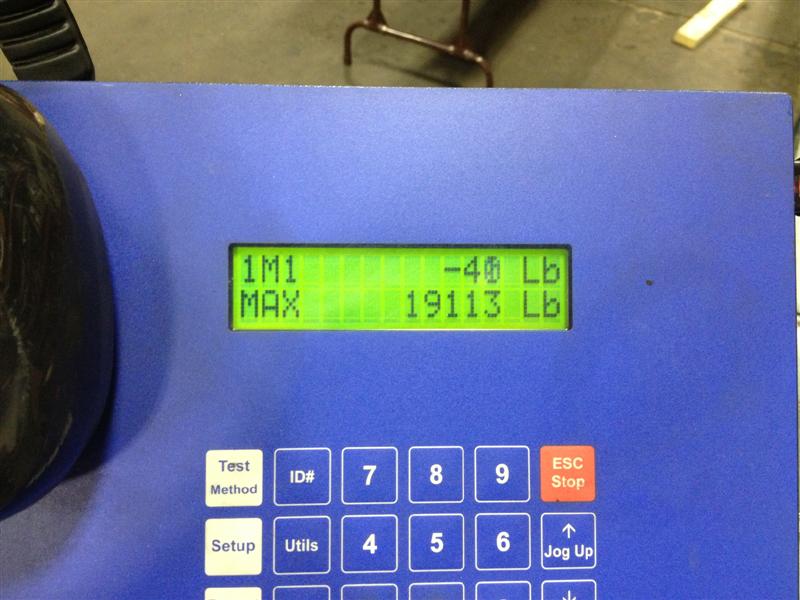

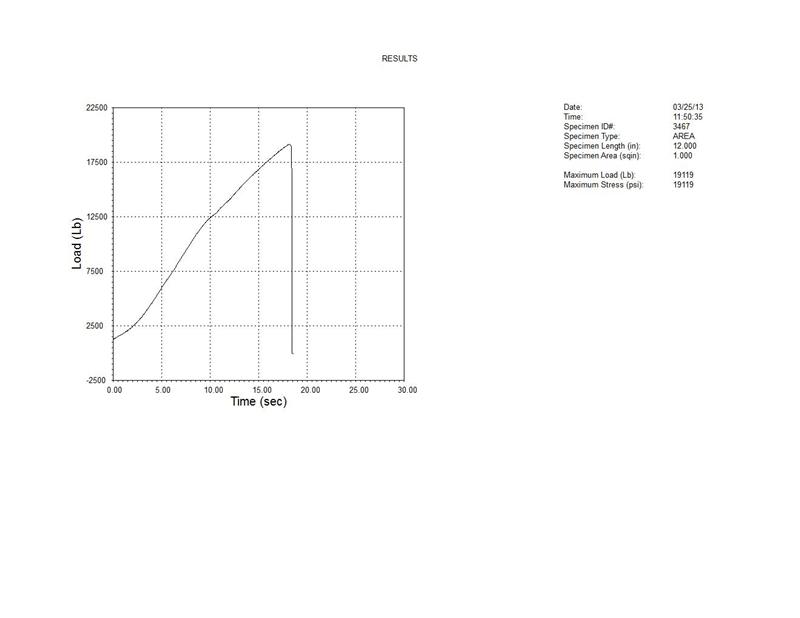

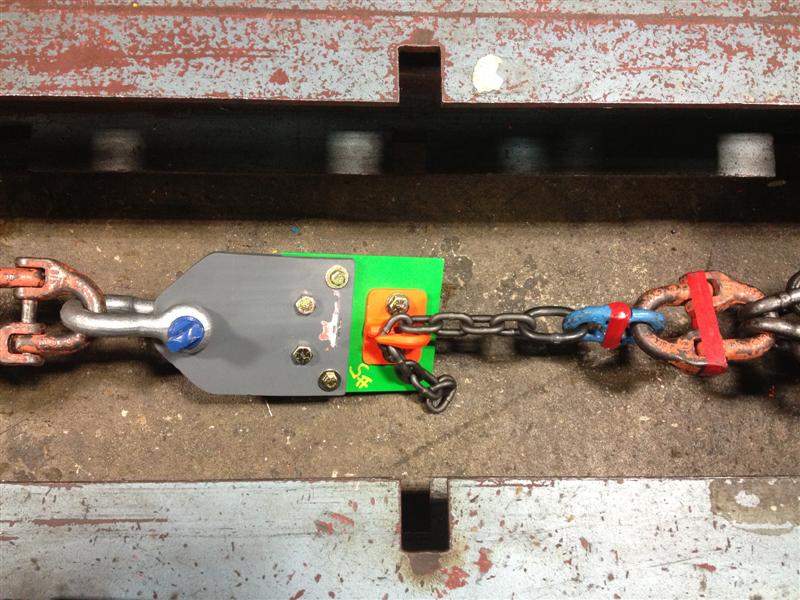

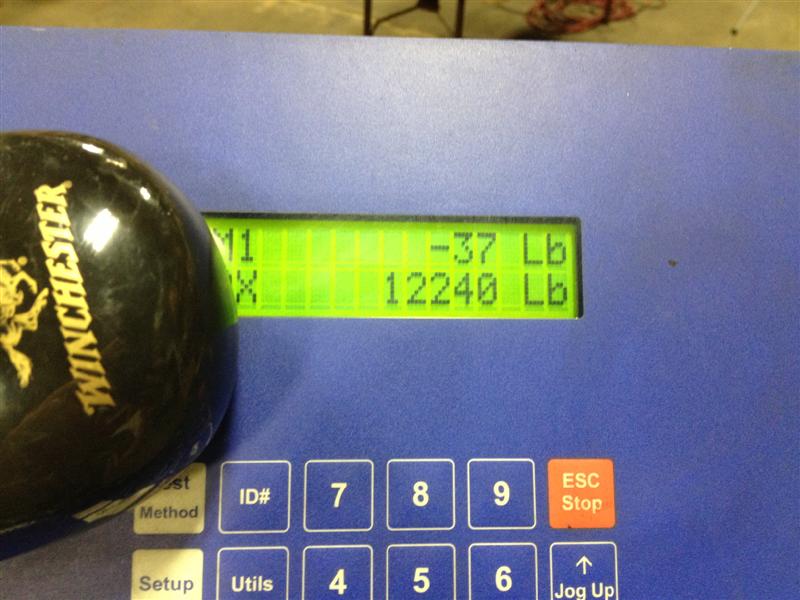

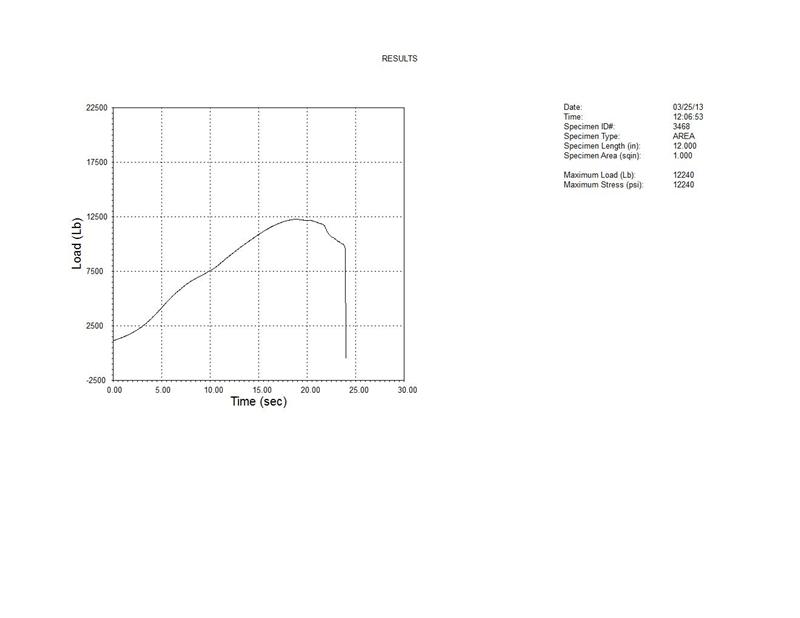

The following five tests where performed on a proof testing sled nicknamed the “Wilburnator” capable of pulling up to 44,000 pounds and recording test data via specialized software. This machine is owned and operated by B/A Products in Columbia, Maryland. A special thanks to Fritz for his assistance and technical expertise in completing these tests.

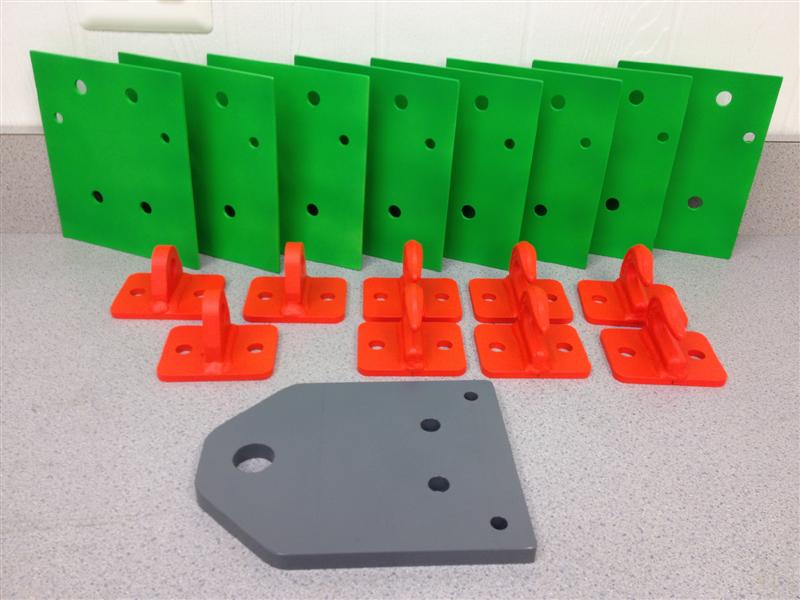

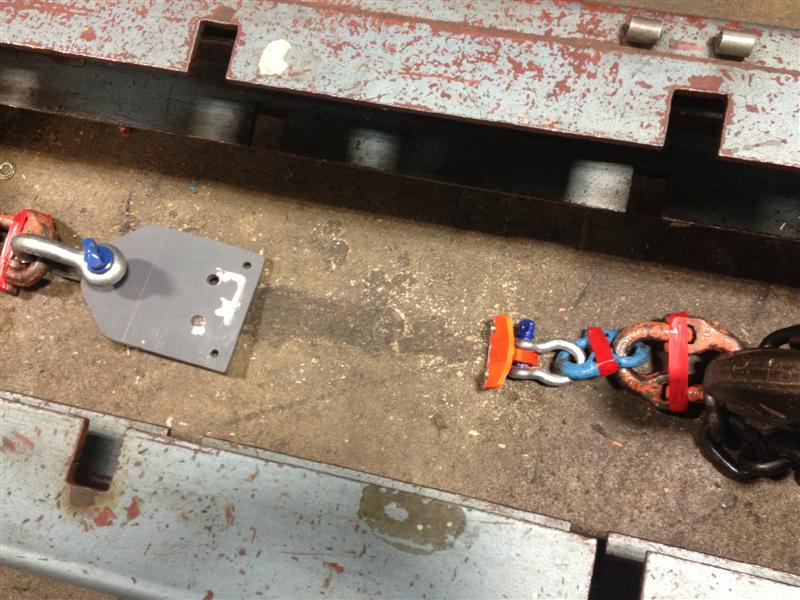

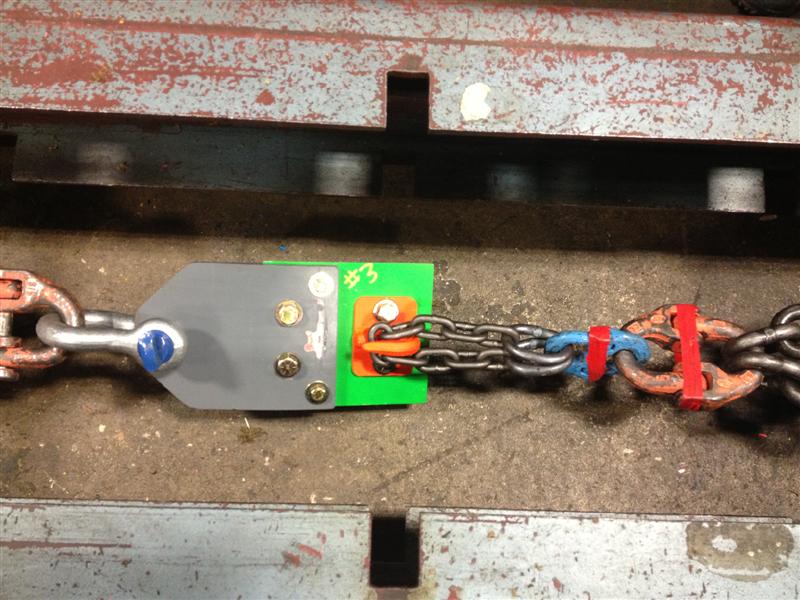

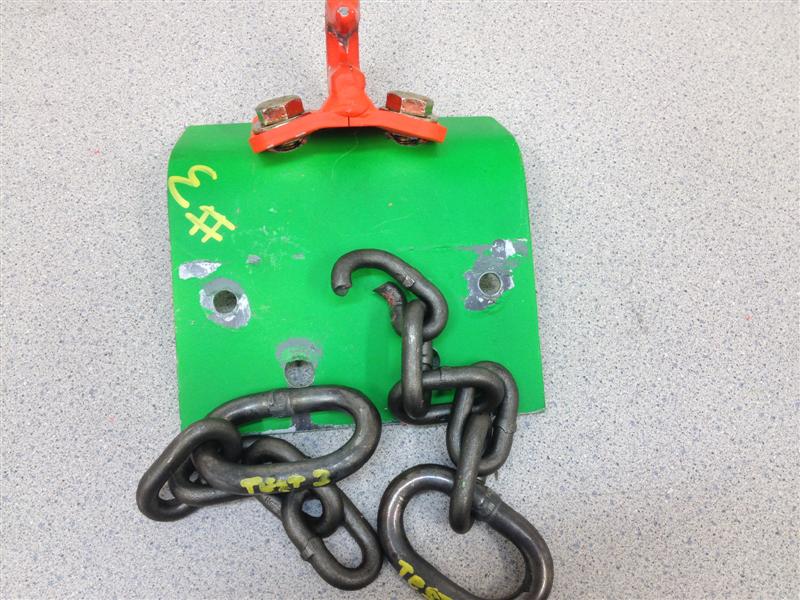

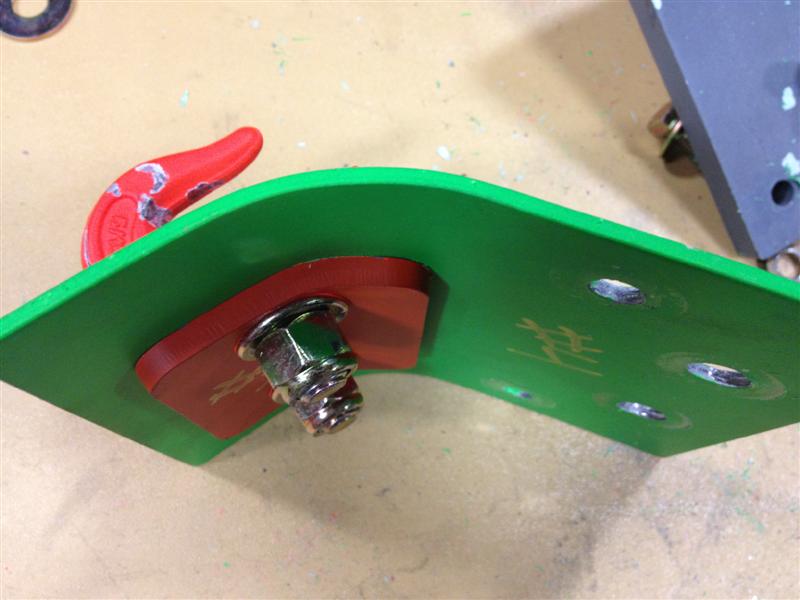

These first pictures are of the Crosby National CN-22 Flatbed Tester, and the samples to be tested. The gray test plate is made from 1/2″ thick A36 steel, and the green plates are #10 gauge (0.1345″) mild steel sheet to simulate the average thickness of a FEL bucket used on a small tractor.